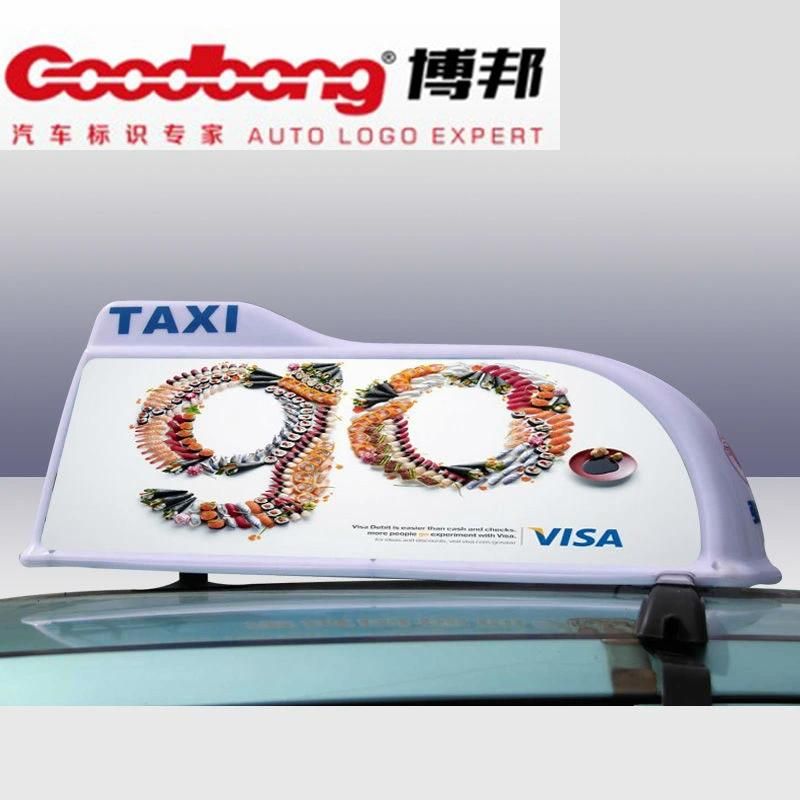

Vacuum Forming Plastic Taxi Advertising Roof Top Light Box

Shanghai Bobang Signage Co., Ltd.- Type:Plastic Light Box

- Usage:Decoration, Advertising

- Material:Acrylic

- IP Rating:IP55

- Shape:Rectangle

- Suitable for:Outdoor

Base Info

- Model NO.:Light Box

- Installation:Magnet and Iron Pull Hook

- Style:Decoration

- Certification:CE, FCC, UL

- Manufacturer:Yes

- Appearance:Smooth, Vacuum Coating

- Color:White

- Shaped:Rectangular,Square

- Size:91*27*36cm

- Keywords:LED Light Box

- Design:Custom-Design Accpetable

- Power Consumpt:8W

- Voltage:12-24V

- Car Make:Any Car

- Advantage:Leakproofness

- Roof Light:Taxi Top Light Box with Magnets

- Types:Taxi Top

- Transport Package:Cartons or Wooden Boxes.

- Specification:ISO 9001, CE, RoHS, UL

- Trademark:Goodbong

- Origin:Shanghai, China

- HS Code:3926909090

- Production Capacity:2000 PCS,Months

Description

Name

New auto taxi top lamp

Model

HT-AD27-SH

Size

91*27*36cm

Process

Lamp shell mould injection one-time

Material

PP + UV additives

Color

White

Light

LED

Voltage

12-24v

Fixed

Iron pull hook,magnet

Car make

Any type

Note

If Qty is large,printing is free,size can be customized.

Goodbong is a professional processing enterprise in china, specialized in large thick vacuum thermoforming, vacuum coating. Since the estabilshment of enterprise,we have based on technology innovation and creation in plastic and electroplate, getting rid of the stale and bringing forth the fresh, advancing with the times, in our service customers, there are about 20 enterprises in world's top 500, hundreds of famous enterprises in the world , the products find a good sales in more than 20 countries, in Germany, France, U.K, Turkey, Japan, Korea, America, Canda, Indonesia etc.

manufacturing process

Manufacture Processing:

We adopt many advantege technologies in the manufacture processing, there are 40 sets of vacuum thermforming machines and the most advanced automatic suction presure blow molding machine in the world.

Raw Material:

All the material must accord with the following standards:

1. The face should be smooth, clean and flat with the same thickness, no area is out of shape;

2. With exactly same color, no color difference;

3. Cutting area is straight and flat, no split or sketch;

4. No concave-convex, no bubble;

5. The sheet must be fit with the graph of the supplier;

6. Non toxic, reach the national environmental protection standard.

The manufacture processing as follow:

1. Pre-treatment

2. Surface cleaning

3. Spray-painting

4. Vacuum Coating

5. UV curing

6. Themal curing

7. Finished products inspection

8. Safe packaging

Packaging:

Inside: wraped with the protective film;

Middle: packed with vacuum bubble;

Outside: cartons or wooden boxes

1. Domestic transport packaging:

For short distance domestic delivery, using stable carton packaging.

2. International transport packaging:

Except delivery of sample with stable carton packaging, all products are packed in wooden boxes, to ensure the safety of the products in transportation.